Plastics are indispensible materials in modern life. One the other hand, the widespread use of plastics demands proper solution to deal with the plastic wastes. Polyolefins, including high density polyethylene (HDPE), low density polyethylene (LDPE), linear low density polyethylene (LLDPE), and polypropylene (PP), constitute more than 60% of the total plastic content of municipal solid waste. One ideal solution to end the life of plastic wastes is to convert them into useful liquid fuels or chemical feedstocks. Among polyolefins, polyethylene (PE) is the largest volume plastic with an annual production exceeding 100 million metric tons. Moreover, PE is chemically inert and difficult to degrade because it is connected by strong single C-C and C-H bonds. Indeed, PE is robust toward oxidation from exposure to heat or UV radiation. Thermal and catalytic pyrolysis processes have been applied to degradation of PE. Unfortunately, the pyrolysis processes typically require very high temperatures (> 400℃) and the product selectivity is low.

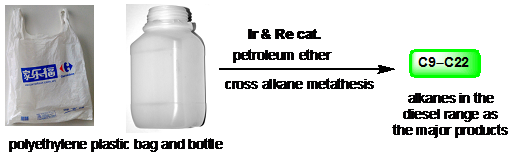

Prof. HUANG Zheng and his coworkers from the Shanghai Institute of Organic Chemistry (SIOC), Chinese Academy of Science, in collaboration with the Prof. GUAN Zhibin and his coworkers from the University of California, Irvine, has recently developed a mild and selective method for degradation of various polyethylenes into valuable liquid fuels and PE waxes. HUANG and his coworkers from SIOC employed a cross alkane metathesis strategy using available dual catalyst systems for PE degradation with inexpensive and widely available light alkanes, such as petroleum ether, as the reagents. Note that these light alkanes can derived readily from refinery and petrochemical streams. First, an iridium catalyst dehydrogenates both PE and a light alkane to form alkenes. Next, a rhenium olefin metathesis catalyst rearranges the alkenes to form two new alkenes, which leads to the breakdown of PE chains. Finally, the newly formed alkenes undergo the iridium-catalyzed hydrogenation to form two new alkanes. The scramble of PE with the light alkane reduces the chain length of PE. In the presence of a large excess of light alkanes, the initial cross alkane metathesis product would react readily with another light alkane to give the secondary cross alkane metathesis products with even shorter chain length. PE will eventually be transformed to liquid hydrocarbons suitable for transportation oils after multiple cycles of cross alkane metathesis with light alkanes. HUANG and coworkers showed that the method is applicable to the degradation of various type of polyethylenes, including HDPE, LDPE, and LLDPE. Even more importantly, they demonstrated that the wastes of commercial PE plastics in real life could be degraded using petroleum ether as the reagent. This method gives high selectivity for the formation of linear alkane formation, Moreover; the degradation product distribution (liquid fuels versus waxes) can be controlled by the reaction time and the catalyst structure. This work has been published online in Science Advances on June 17(Sci. Adv., 2016, 2, e1501591).

Degradation of polyethylene plastic bag and bottle.(Imaged by HUANG Zheng)